Precision in Hookah Wall Thickness Control — The Hand-Blown Expertise of luxcry Crystal

Core Keywords: hookah wall thickness control, hookah glass forming, hookah glass durability

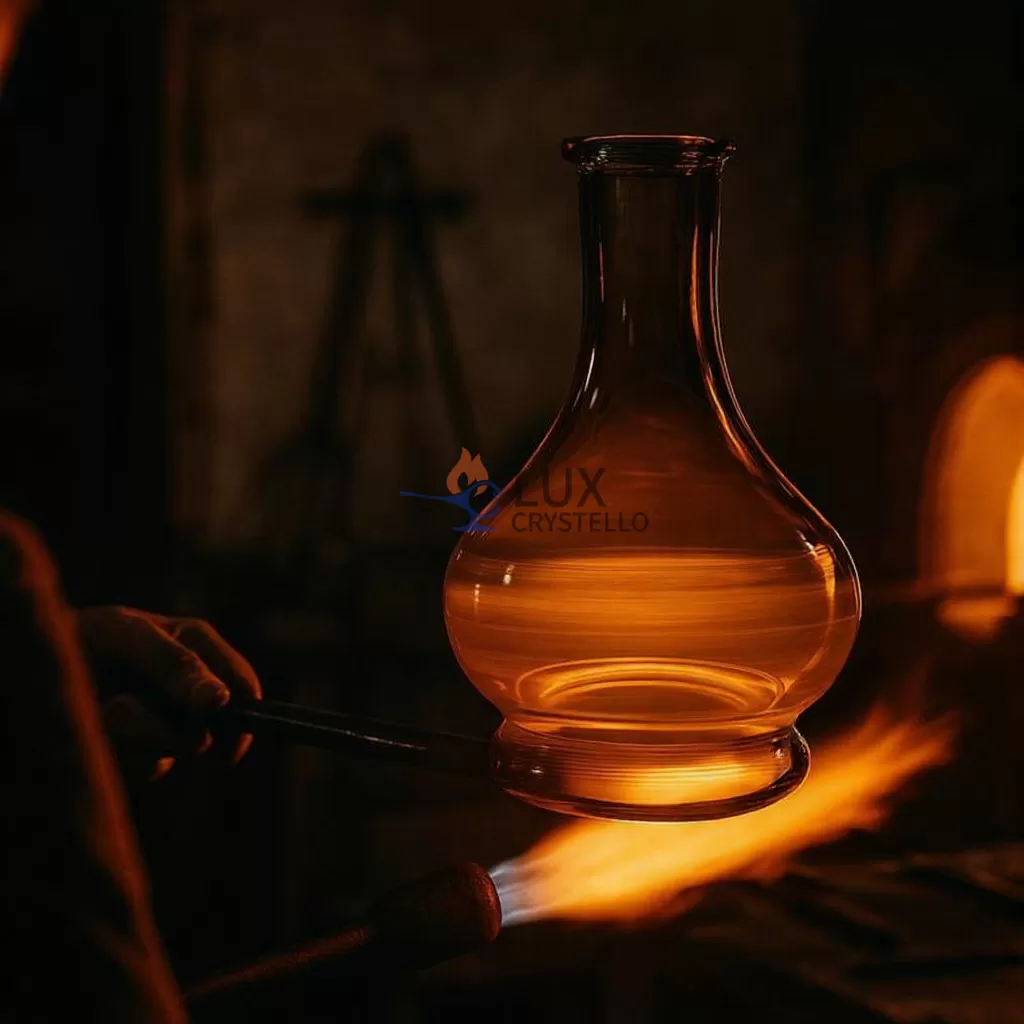

In the world of hand-blown hookah craftsmanship, hookah wall thickness control defines where artistry meets engineering. Every measured breath of the glassblower shapes the balance between form, strength, and longevity. At Luxcrystello Crystal, this equilibrium is achieved not through automation but through refined hookah glass forming methods guided by human intuition and decades of experience.

Wall consistency may be invisible, yet it determines airflow stability, heat tolerance, and hookah glass durability. For both manufacturers and buyers, steady thickness is the foundation of dependable, export-grade hookah bases—an unseen detail that protects beauty with structure.

Hookah Wall Thickness Control — The Art Beneath Hand-Blown Perfection

True mastery in glassmaking lies in guiding molten material while it’s still breathing with heat and motion. Luxcrystello Crystal’s artisans approach hookah glass forming as a dialogue with molten material—using rhythm, timing, and temperature to achieve even curvature. Each breath redistributes glass mass, eliminating weak zones and ensuring a flawless contour.

Unlike automated systems, hand-blown production allows instinctive correction. Each artisan senses the rhythm of the flame—its hue, viscosity, and flow—to maintain the perfect harmony of shape and thickness. This tactile precision has become a benchmark of hookah glass durability, proving that consistent shaping can create bases that remain clear, strong, and elegant after years of use.

For Manufacturers — Precision as a Signature

For producers, control begins at the furnace edge. Luxcrystello Crystal’s artisans rely on visual calibration and disciplined repetition to sustain wall uniformity. Each piece is examined under transmitted light to detect irregularities before annealing.

This focus on accuracy enhances hookah glass durability by distributing stress evenly and minimizing tension zones. The final product shows remarkable consistency, with wall variation held within ±0.3 mm, confirmed through precise manual measurement and visual alignment. Quality audits show that 95% of pieces meet this tolerance, reducing fracture incidents by nearly 25% during cooling.

Consistent results translate into lower waste, higher yield, and stronger brand credibility. Within Luxcrystello Crystal, hookah wall thickness control is not merely a technical term—it’s the language of craftsmanship that defines authenticity.

For Buyers — Stability You Can See and Feel

For every buyer, the result is tangible balance: a base that stands solidly, looks refined, and feels naturally weighted in the hand.

Every curve carries both aesthetic beauty and engineered assurance, reflecting the subtle control behind Luxcrystello Crystal’s hand-blown precision.

Even wall distribution supports smoother airflow and consistent pressure, resulting in a refined smoking experience. The same uniformity also enhances hookah glass durability, allowing the base to resist rapid temperature changes, frequent washing, and long-term commercial use.

Visually, controlled wall depth improves light refraction and optical clarity—attributes that distinguish Luxcrystello Crystal’s craftsmanship in high-end retail and lounge markets worldwide.

Shared Value Between Maker and Market

Both artisans and clients pursue a common goal: reliability through craftsmanship.

At Luxcrystello Crystal, every base is hand-shaped, cooled, and inspected for wall symmetry. The slow annealing process releases internal tension while preserving the geometry achieved through meticulous hookah glass forming. The outcome is a perfect equilibrium—handmade precision that meets international standards while maintaining soul and authenticity.

As global markets continue to favor transparent quality and verified performance, hookah wall thickness control remains a lasting benchmark. It proves that perfection doesn’t depend on automation but on mastery, patience, and human skill.

Work With Luxcrystello Crystal — Where Tradition Becomes Measurable Quality

Collaborate with Luxcrystello Crystal to experience how hookah wall thickness control, hookah glass forming, and hookah glass durability together shape the foundation of excellence.

Our artisans merge traditional hand-blown artistry with measurable consistency, ensuring every base delivers strength, clarity, and balance.

Whether you are a distributor, brand owner, or designer, Luxcrystello Crystal helps you turn creative vision into reliable form—one handcrafted hookah at a time.

FAQ

What is hookah wall thickness control and why is it important?

Hookah wall thickness control refers to the precise management of the glass thickness throughout a hookah base during manufacturing. It is critical because consistent thickness ensures structural integrity, even heat distribution, optimal airflow, and overall hookah glass durability, preventing weak points that can lead to cracking.

How does hand-blown hookah glass forming achieve uniform thickness?

In hand-blown hookah glass forming, skilled artisans use their breath, rotation, and tools to manipulate molten glass. Through experience and visual/tactile feedback, they achieve uniform thickness by carefully controlling the speed of rotation, the intensity of heating, and the timing of inflation, ensuring an even distribution of material.

How does wall thickness affect hookah glass durability?

Even wall thickness directly enhances hookah glass durability by distributing mechanical and thermal stress uniformly. This prevents localized weak spots, reduces the risk of cracking from impact or temperature shock, and ensures the base can withstand regular cleaning and long-term use.

Can automated processes match the precision of hand-blown thickness control?

While automation offers high consistency for simple shapes, the complex curves and subtle contours of premium hookah bases often benefit from the adaptive skill of hand-blown hookah glass forming. Artisans can make real-time adjustments that machines cannot, achieving a level of precision and quality that supports superior hookah wall thickness control.

Partner with experts who master the art of precision. Contact Luxcrystello Crystal today to develop hookah bases defined by craftsmanship and durability.